SLG 56

Designed for Mini Excavators and Sub Compact Tractors

5 to 10 Yards Per Hour

$3,495 CAD

What do you have ?

Mini Excavator

Stand on Skidsteer

Mini Tractors

GENERAL DESCRIPTION

The SLG 56 MINI SCREENER is the only screener specifically designed for mini equipment, making it an ideal solution for small-scale screening projects and operations. With an hourly production rate of 10 yards, it is the most affordable screener in our lineup, perfect for those who need efficient screening without the high cost.

YOU CAN SCREEN

- Sand

- Topsoil

- Compost

- Wood Mulch

- Pea Stone

- Septic Rock

- Road Gravel

- Landscape Stone

- Ground Asphalt

- Crushed Concrete

- Erosion Control Rock

- Traction Sand

SCREENER FEATURES

C SPRING SUSPENSION SYSTEM

The C Spring Suspension System, just like in our other models, is crucial for enabling the action and reaction of the screen deck during the screening process. In the SLG 56 MINI SCREENER, this system is especially important because it is a static screener, meaning it does not have a vibratory pack. The C Spring Suspension System ensures that the material moves smoothly across the screen deck, maintaining efficiency and effectiveness in the screening process.

REMOVABLE WHEELS SYSTEM

Unlike our larger models that come with bucket transport lugs, the SLG 56 MINI SCREENER is designed with a lightweight and compact build, allowing for easy mobility. To accommodate this, we've equipped the machine with removable wheels. Depending on the state of the machine, such as during the screening process, these wheels can be quickly removed and stored to prevent any damage when using your equipment. This user-friendly system allows you to remove or attach the wheels in less than 5 minutes, ensuring seamless transitions between transport and operation.

QUICK DISCONNECT HITCH SYSTEM

The Quick Disconnect Hitch System allows for easy mobility of our SLG 56 MINI SCREENER. You can quickly detach the hitch and store it during the screening process, or reattach it when you need to move the machine. This system is designed for simplicity and efficiency, enabling the user to complete the process in less than 5 minutes, ensuring smooth transitions between screening and transport.The SLG 78VF can be powered by standard 120-volt electricity, provided the distance from the power source is under 75ft and a heavy-duty 10-gauge electrical cord is used, ensuring flexibility and convenience in various operational settings.

RUBBER SCREEN DECK SKIRTS

The SLG 56 MINI SCREENER features robust rubber skirts along each side of the screen deck, designed to serve as a protective barrier. These skirts effectively catch any loose material that may escape from the bucket, preventing debris from spilling over and maintaining a cleaner, more organized work environment.

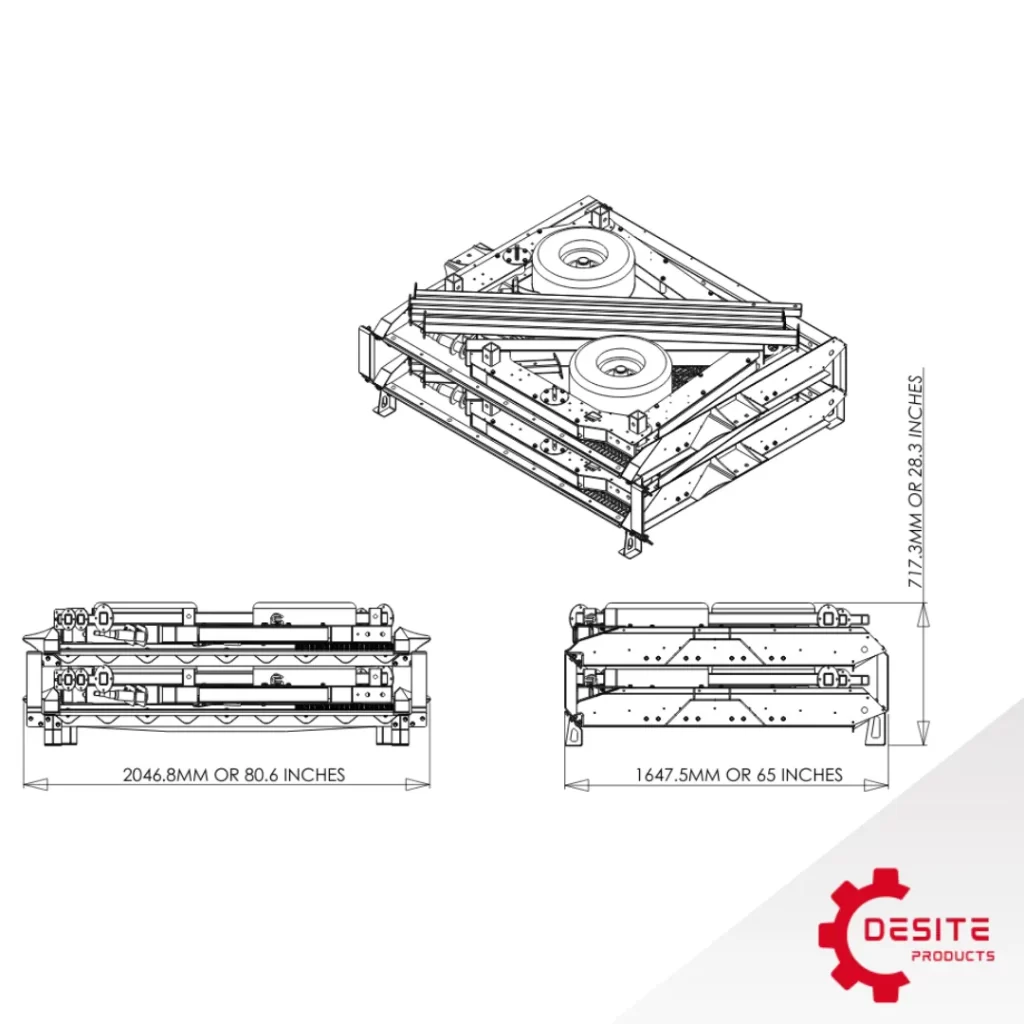

MACHINE SPECIFICATIONS

| MACHINE DIMENSIONS | |

|---|---|

| Machine Width | 74 inches |

| Machine Height | 61.4 inches |

| SCREEN DECK | |

| Screen Deck Width | 63 inches |

| Screen Deck Length | 66 inches |

| Screen Deck Surface area | 33 sq/ft |

| Screen Deck Tilt Angle | 45 to 30 Degrees |

| WEIGHT | |

| Total Weight | 991 lbs |

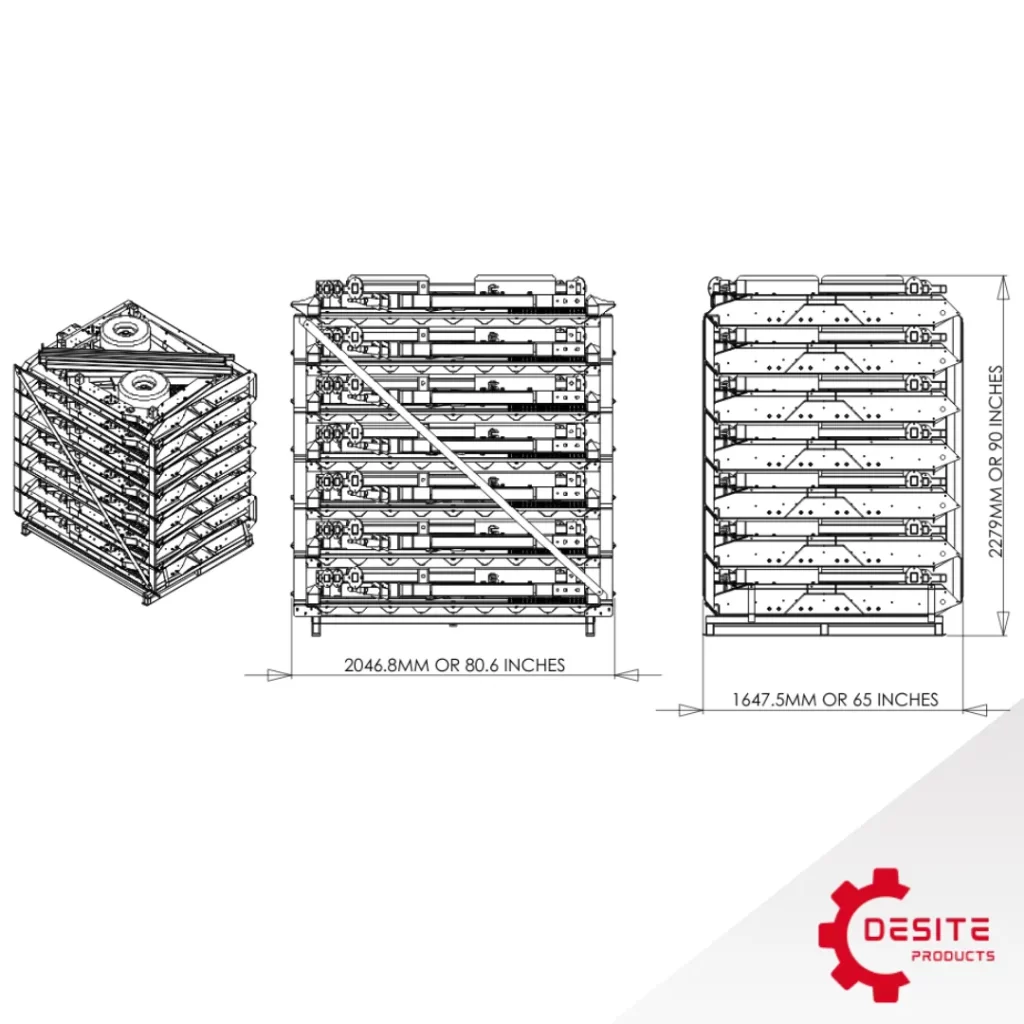

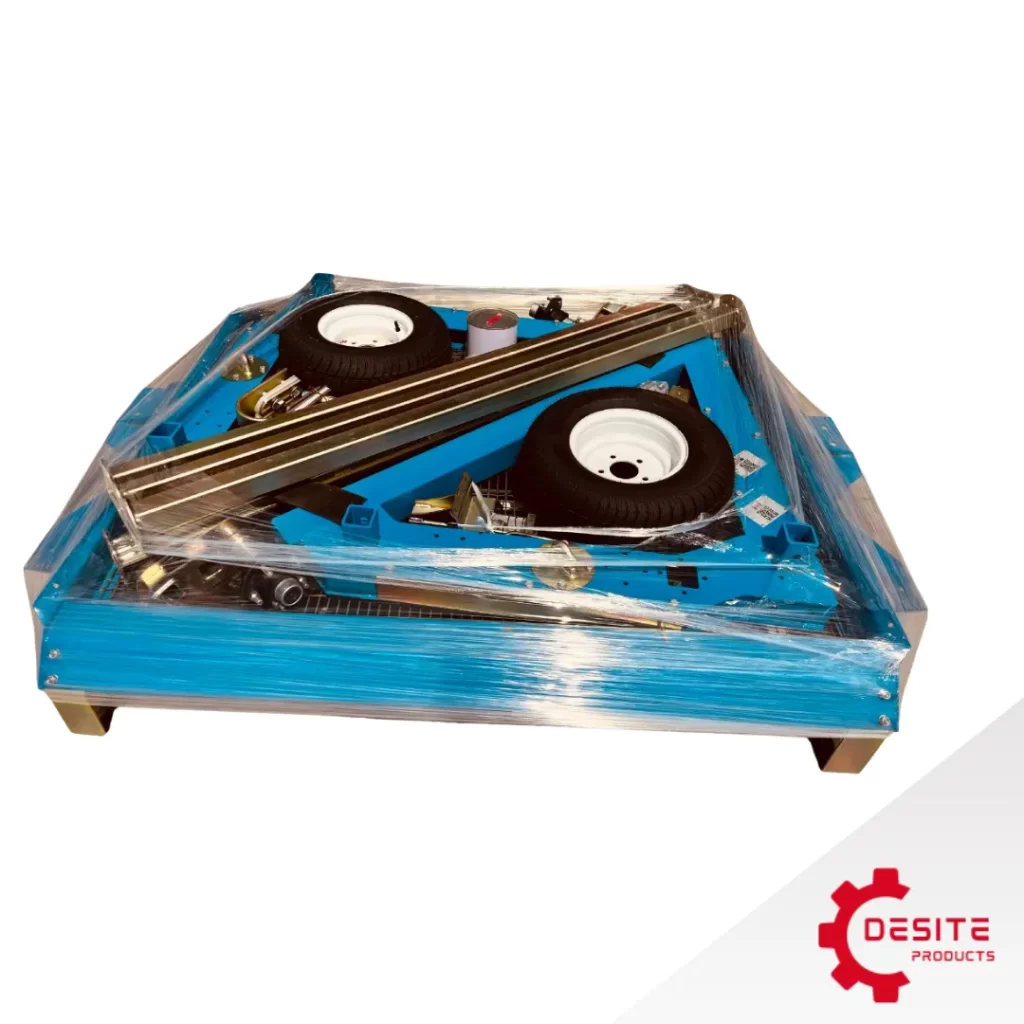

SHIPPING EFFICIENCY

DeSite ENGINEERS AND DESIGNS OUR PRODUCTS WITH SHIPPING EFFICIENCY

1.5 Hrs for Assembly

For customers who would like to avoid the "Assembly Fee" we have flat packed and designed the 56 screener for quick and easy single unit loadout. Designed for efficiency It takes less than five minutes to remove a packaged unit.

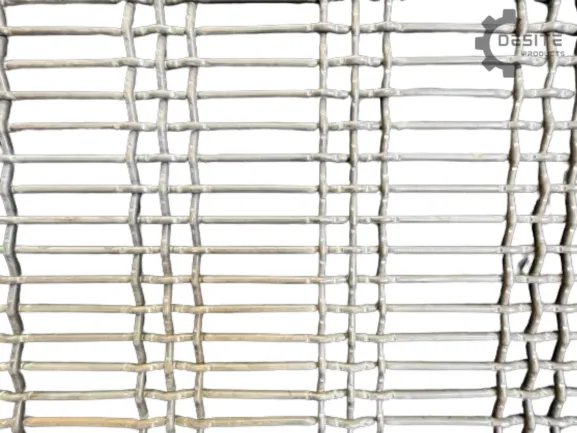

ABOUT MESH

TALK ABOUT MESH

square

We offer a wide range of mesh that are quick and easily changed.The ability to install large and small high quality mesh makes DeSite SLG Screeners a time saver and money maker. We offer both square and elongated mesh pattern in a double lock crimp weave. Our double lock weave puts two crimps in each wire as they intersect, This creates a strong weave and a stronger, more stable mesh.By directing material flow to the top of the screen deck, this system ensures maximum production and efficiency. The SLG 108's deflector is designed with flexibility in mind, allowing it to open and close as needed to manage oversized materials effectively. Additionally, the 108's feed deflector fits into our quick disconnect lugs, making it easy to remove when necessary.

Elongated

Our elongated pattern mesh is what we call a triple chute weave where a group of three wires intersect the main with wires. A space of four inches has full unobstructed opening before the next three wires intersect the mesh again. Our elongated pattern meshes are designed to handle higher moisture material when screening is more challenging. Hourly production are always considerably higher when elongated pattern mesh in in use.

MESH GUIDE

square

| Mesh Size | Pattern | Product Size |

|---|---|---|

| 5/32" x 5/32" | Square | 1/16" |

| 1/4" x 1/4" | Square | 1/8" |

| 3/8" x 3/8" | Square | 1/4" |

| 1/2" x 1/2" | Square | 3/8" |

| 1" x 1" | Square | 3/4" |

| 2" x 2" | Square | 1-1/2" |

| 3" x 3" | Square | 2" |

| 4" x 4" | Square | 3" |

Elongated

| Mesh Size | Pattern | Product Size |

|---|---|---|

| 3/8" x 4" | Elongated | 1/4" to 5/16" |

| 1/2" x 4" | Elongated | 3/8" to 7/16" |

| 3/4" x 4" | Elongated | 1/2" to 9/16" |

| 1" x 4" | Elongated | 3/4" to 7/8" |

SCREEN MESH RECOMENDATION CHART

Topsoil and Triple Mix

Topsoil is in demand and profitable. Depending upon the customer and their needs some want it very fine while other are more price conscious and want commercial grade topsoil.

| Mesh Size | Product Size |

|---|---|

| 1/8 x 4” elongated mesh | 1/16 minus product |

| 1/4 x 1/4 square mesh | 1/8 minus product |

| 1/4 x 4” elongated mesh | 1/8 minus product |

| 3/8 x 3/8 square mesh | 1/4 minus product |

| 3/8 x 4” elongated mesh | 1/4 minus product |

| Mesh Size | Product Size |

|---|---|

| 1/4 x 4” elongated mesh | 1/8 minus product |

| 3/8 x 4” elongated mesh | 1/4 minus product |

| 1/2 x 4” elongated mesh | 3/8 minus product |

COMPOST

Compost and either be a top dressing product used fertilizer / soil builder or can be used to create a triple mix with sand and topsoil.

| Mesh Size | Product Size |

|---|---|

| 3/8 x 3/8 square mesh | 1/4 minus product |

| 3/8 x 4” elongated mesh | 1/4 minus product |

| 1/2 x 1/2 square mesh | 3/8 minus product |

| 3/4 x 4” elongated mesh | 1/2 minus product |

| 1” x 4” elongated mesh | 3/4 minus product |

| 1” x 1” square mesh | 3/4 minus product |

Wood Mulch

Wood mulch is a light product that travels over the screen deck differently that a soil or aggregate product. It is recommended to run a bit bigger mesh. Often people will screen out the fines and mix it into the topsoil for slow release decomposition. It is a great way to recycle the wood fines.

| Mesh Size | Product Size |

|---|---|

| 1/2 x 1/2 square mesh | 1/4 minus product |

| 3/4 x 4” elongated mesh | 1/2 minus product |

| 1” x 4” elongated mesh | 3/4 minus product |

| 1” x 1” square mesh | 1/2 minus product |

| 2” x 2” square mesh | 1-1/4 minus product |

| 3” x 3” square mesh | 2” minus product |

| 4” x 4” square mesh | 3” minus product |

Commercial Grade or Triple Mix Topsoil

This is the mixture of topsoil / sand / compost to create a product that normally commands a premium price.

| Mesh Size | Product Size |

|---|---|

| 1/2 x 1/2 square mesh | 1/4 minus product |

| 3/4 x 4” elongated mesh | 1/2 minus product |

| 1” x 4” elongated mesh | 3/4 minus product |

| 1” x 1” square mesh | 1/2 minus product |

| 2” x 2” square mesh | 1-1/4 minus product |

| 3” x 3” square mesh | 2” minus product |

| 4” x 4” square mesh | 3” minus product |

Aggregate Products

Pea Stone

Often used in play grounds or for decoration. Pea stone usual commands a premium price asmost aggregate gets crushed and too sharp for pea stone.

| Mesh Size | Product Size |

|---|---|

| 3/8 x 3/8 square mesh | 1/4 minus product |

| 1/2 x 1/2 square mesh | 3/8 minus product |

| 1/2 x 4” elongated mesh | 3/8 minus product |

| 1” x 1” square mesh | 3/4 minus product |

Decorative Stone

In some regions water is restricted for yard use so decorative rock is the manageable and cost effective solution.

| Mesh Size | Product Size |

|---|---|

| 3/4 x 4” elongated mesh | 5/8 minus product |

| 1” x 1” square mesh | 3/4 minus product |

| 1-1/4 x 1-1/4 square mesh | 7/8 minus product |

| 1-1/2 x 1-1/2 square mesh | 1-1/8 minus product |

| 2” x 2” square mesh | 1-1/2 minus product |

| 3” x 3” square mesh | 2-1/4 minus product |

| 4” x 4” square mesh | 3-1/4 minus product |

Top Coarse Gravel

Finer road gravel works great for capping roadways.

| Mesh Size | Product Size |

|---|---|

| 3/4 x 4” elongated mesh | 5/8 minus product |

| 1” x 1” square mesh | 3/4 minus product |

| 1-1/4 x 1-1/4 square mesh | 7/8 minus product |

| 1-1/2 x 1-1/2 square mesh | 1-1/8 minus product |

Septic Stone

Many regions still use stone in their septic fields for the evaporation process.

| Mesh Size | Product Size |

|---|---|

| 1/2 x 1/2 square mesh | 3/8 minus product |

| 3/4 x 4” elongated mesh | 5/8 minus product |

| 1” x 1” square mesh | 3/4 minus product |

| 1-1/4 x 1-1/4 square mesh | 7/8 minus product |

Base Rock Gravel

The ability to separate out the smaller gravel make for a much better and more stable road base. I also then allows for the fines to be spread on top of the base coarse for a gradable surface.

| Mesh Size | Product Size |

|---|---|

| 1-1/2 x 1-1/2 square mesh | 1-1/8 minus product |

| 2” x 2” square mesh | 1-1/2 minus product |

| 3” x 3” square mesh | 2-1/4 minus product |

| 4” x 4” square mesh | 3-1/4 minus product |

Ground Asphalt

The screening and recycling of ground asphalt has become popular with the material coming in off repaving project. Once screened many people use the fine material on driveways and the bigger material on roads and lots with heavier traffic.

| Mesh Size | Product Size |

|---|---|

| 3/4 x 4” elongated mesh | 5/8 minus product |

| 1” x 1” square mesh | 3/4 minus product |

| 1-1/4 x 1-1/4 square mesh | 7/8 minus product |

| 1-1/2 x 1-1/2 square mesh | 1-1/8 minus product |

| 2” x 2” square mesh | 1-1/2 minus product |

Crushed Concrete

Screened crushed concrete makes great base material when building roads.

| Mesh Size | Product Size |

|---|---|

| 3/4 x 4” elongated mesh | 5/8 minus product |

| 1” x 1” square mesh | 3/4 minus product |

| 1-1/4 x 1-1/4 square mesh | 7/8 minus product |

| 1-1/2 x 1-1/2 square mesh | 1-1/8 minus product |

| 2” x 2” square mesh | 1-1/2 minus product |

| 3” x 3” square mesh | 2-1/4 minus product |

| 4” x 4” square mesh | 3-1/4 minus product |

Erosion Control Rock

Water flow can do a lot of damage through erosion. Erosion control rock works great to stabilize slopes or around culverts to reduce erosion during heavy rains.

| Mesh Size | Product Size |

|---|---|

| 1/2 x 4” elongated mesh | 3/8 minus product |

| 3/4 x 4” elongated mesh | 1/2 minus product |

| 1” x 4” elongated mesh | 3/4 minus product |

| 1” x 1” square mesh | 3/4 minus product |

| 1-1/4 x 1-1/4 square mesh | 7/8 minus product |

| 1-1/2 x 1-1/2 square mesh | 1-1/8 minus product |

- Phone: 1(877) 254-7903

-

Address:

20 Jackson Lane, Arnprior, ON K7S 3G.

6935 Cariboo Hwy 97, Clinton BC V0K 1K0. - Email: [email protected]